* Some products require configurations and options that can affect pricing.

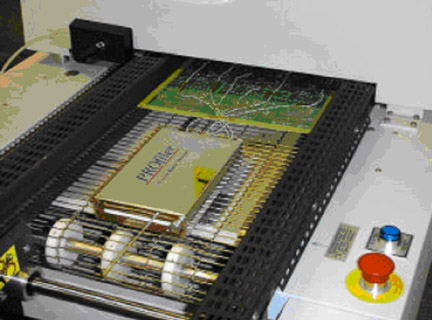

PROfiler is a six channel high accuracy RF temperature profiling system which allows temperature profiles to be gathered and viewed in real time. Suitable for industries that need to log high accuracy temperatures from hostile environments. PROfiler is ideal for use in food, industrial and electronic production processes where thermal process profiling is fundamental to product quality. Other applications are within the ceramics, glass and metal finishing industries. The standard PROfiler datalogger unit is fitted with six Type-K thermocouple channels, offering unprecedented measurement accuracy. Using high performance data acquisition circuitry and digital filtering techniques, accurate profiles can be gathered with high levels of 50-30Hz Mains noise rejection. At least 10,000 data points per channel can be held within the loggers memory, while the RF real time telemetry system offers the benefits of seeing the profile as it happens. A two-way RF protocol is used between the datalogger and PC, resulting in zero data loss during transmission, therefore all the data you see is 'real' data. The datalogger unit is fitted with Ni-MH rechargeable batteries and uses intelligent battery management to optimize use between recharges. THERMAL BARRIERS: To protect the PROfiler datalogger unit from the harsh high temperature environments, a robust thermal barrier manufactured from stainless steel is used, which is suitable for most process requirements. On edge feed ovens with reduced aperture height or when profiling PCB wider than the thermal barrier an optional carrier is used to transport the system through the process. Choosing the right barrier: Before making your choice, you should consider the parameters of your own process(es) and contact us with the details. SOFTWARE: the PROfiler analysis software will run on any PC with Microsoft Windows 95/98/NT/XP installed, utilizing one standard serial communications port. Using RF telemetry a full screen temperature/time graph can be displayed in real time allowing process engineers to make rapid process decisions and minimize production down time. Profiles can also be gathered and stored by the datalogger for download later to a PC. Once a profile has been captured, it can be analyzed with easy to use software tools and saved to disk for future reference. A report sheet can also be printed detailing process parameters, logger details and the captured profile for total traceability of your soldering process. An optional prediction software module is also available which enhances the offline capabilities of the system.

Features:

Specifications:

| Part # | Description | Price (USD) |

| CM0100 | 6 channel PROfiler (non-RF) with standard barrier | Call for Pricing |

| CM0200 | 6 channel PROfiler RF with standard barrier | Call for Pricing |

| CM0300 | High Temperature Thermal Barrier, 350C for 10 minutes | Call for Pricing |